Laboratory Control

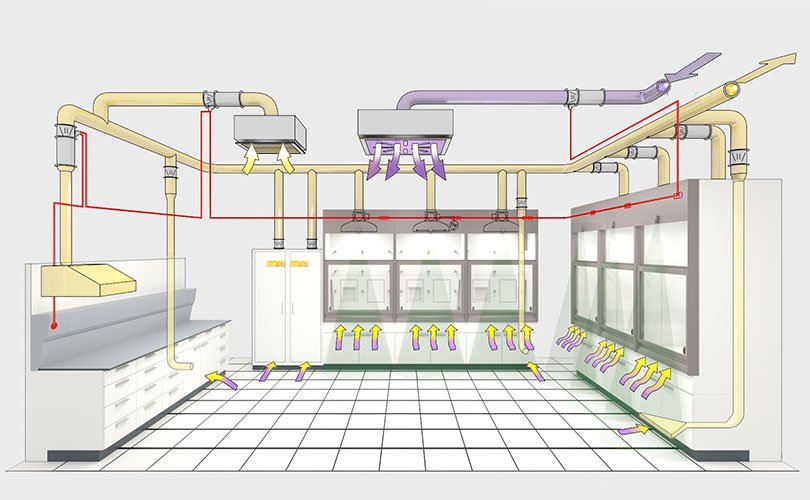

Fume Hoods are not standalone devices and form a critical part of the overall lab ventilation system. Proper integration between the hood controllers, room controllers, and building systems is essential for a safe and energy-efficient lab space. At GD Waldner, we have learned from decades of project experience and developed our own laboratory control that helps to create customer-specific, adaptable laboratory control systems with the highest degree of energy efficiency. The GD Waldner Airflow-Controller AC4 is the latest version of our laboratory control system. Demand-led air flow damper control provides for the energy-optimized operation of laboratories and thus maximum safety and efficiency, thereby helping us to create the labs of the future today.

Master Function for Room Control

The AC4 module records the individual exhaust air volumes of all the exhaust units in the laboratory and calculates a total air volume from this. Some of the key features include

- Minimum air changes per hour are regulated based on different operating statuses (e.g., daytime operation, night setback. Individual device exhaust volumes can be controlled based on this.

- Automatic alarm in case of deviations from the target values.

- Maximum energy efficiency through real-time Variable Air Volume (VAV) regulation.

Benefits

Air flow damper control depending on the sash position

When the sash is closed, the extract air volume is automatically reduced and increased as required when the sash is open.

- Reduced energy consumption

- Optimized operating costs

Combination sash controller SC

A motion sensor monitors the sash of the fume hood. If no movement is detected in front of the fume hood within a specified period of time, the sash closes automatically.

- The highest safety standards in the laboratory, thanks to closed sashes

- The best energy savings in conjunction with the VAV extract air system (Airflow-Controller)

Night setback mode

The room air exchange is regulated to a minimum value at night.

- Reduction in night operation to 100 m³/h

- Maximum energy savings

High-speed actuator

The air flow damper needs to regulate quickly and precisely for a fume hood to guarantee its protective pollution retention objectives. This guarantees that the required extract air volume flow is ensured when the sash is opened.

- Response time for adjustment of the volume flow when the sash is open is less than one second

- Maximum safety standards when operating the fume hood

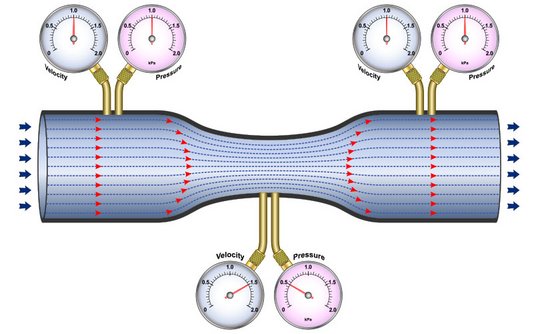

Venturi effective pressure detection

The sound pressure level of ventilation systems must be kept below 52 dB(A) in accordance with DIN 1946 Part 7. To minimise the impact of the extract air volume control on the sound emissions, Waldner uses flow-optimised volume flow measurements based on the Venturi principle.

- Extremely quiet operation: Reduction of the sound (capacity) level by up to 10 dB(A)

- Increased energy efficiency: Reduced pressure loss of 15 Pa; pressure loss specification reduced by 10 %

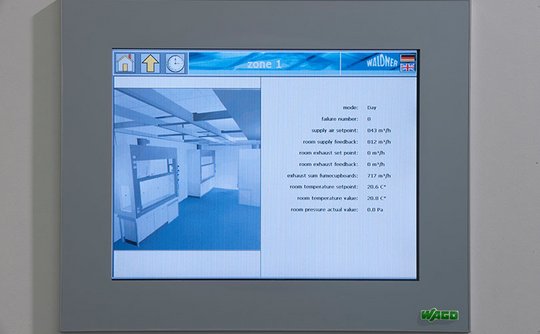

Control panel

The display shows system-relevant data, such as target and actual values, energy consumption data, function of the Secuflow fan, maintenance intervals as well as warnings and alarms.

- Fast and clear communication

- Consumption monitoring

- Error analysis

Standardised solution

The fume hood and control are perfectly coordinated with AC4.

- One point of contact for the safe operation of the fume hood

- Clear CE marking, type-tested according to EN 14175-6

BTL-certified BACnet connection

BACnet, which complies with the ASHRAE 135 and ISO 16484-5 standards, has established itself as a standard for communication between control components in laboratories and the building management system (BMS).

- Defined BIBBs (BACnet Interoperability Building Blocks)

- Fast connection

- Optimum project management

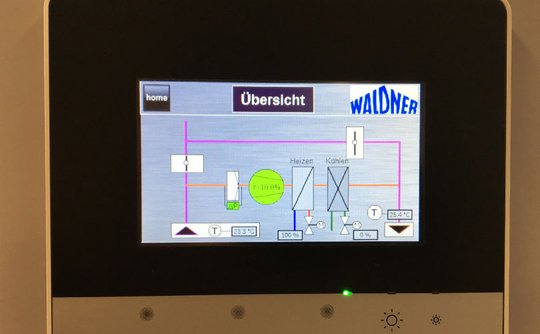

Integrated systems

From the simple stand-alone solution using air management with all the required air flow dampers to comprehensive laboratory control with temperature (heating/cooling), light and shading

- Modular system with integrated concept

- CANopen networked control modules

- Extensive monitoring and automation options